project01:Group1

DIA/TUD RB | GROUP 1

Group 1 members: Dylan Deguzman, Olav van der Doorn, Daniel Fischer, Nikhil Kowshik, Turkuaz Nacafi, Saurabh Prasadi, Hilde Rosenboom, Erik Zanetti

Final

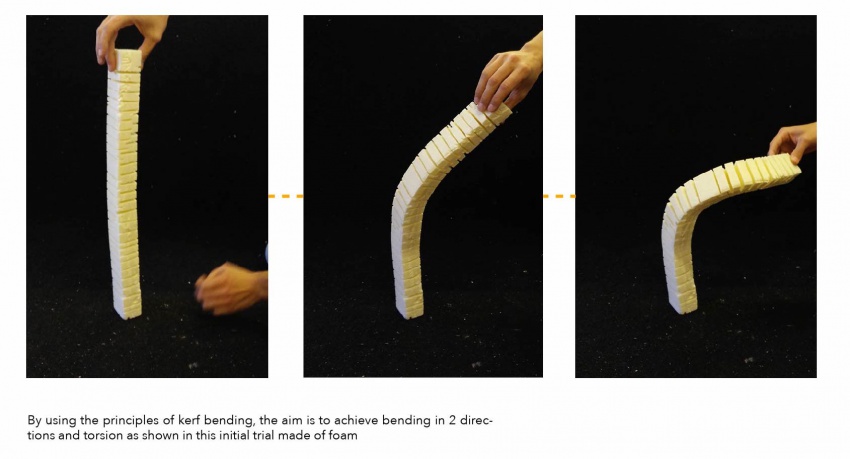

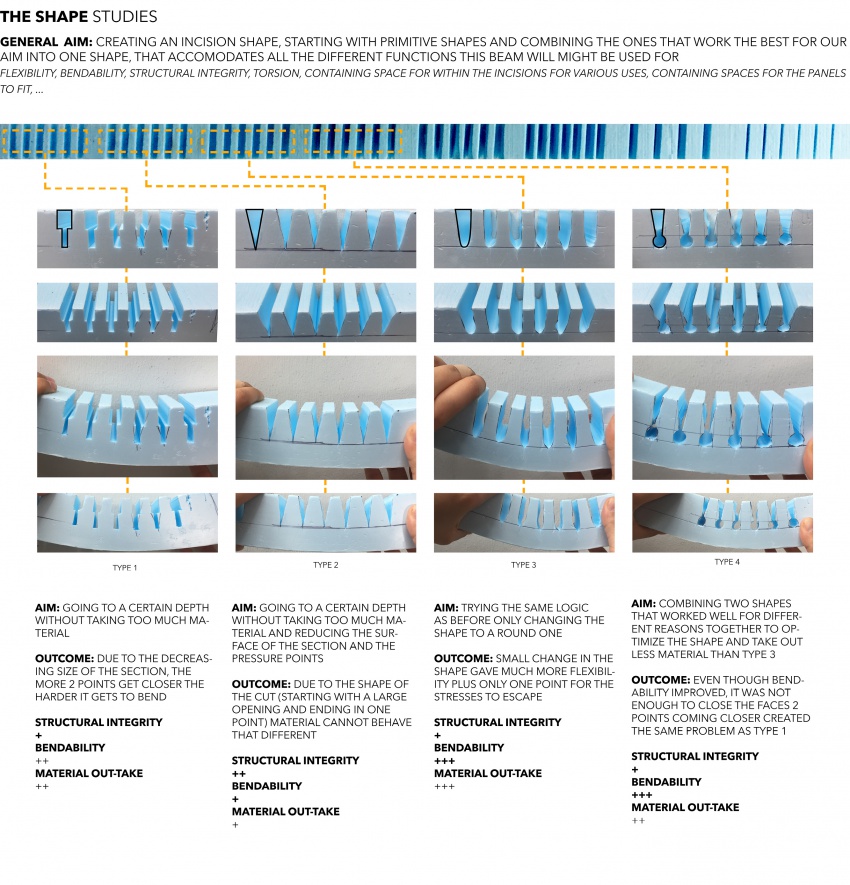

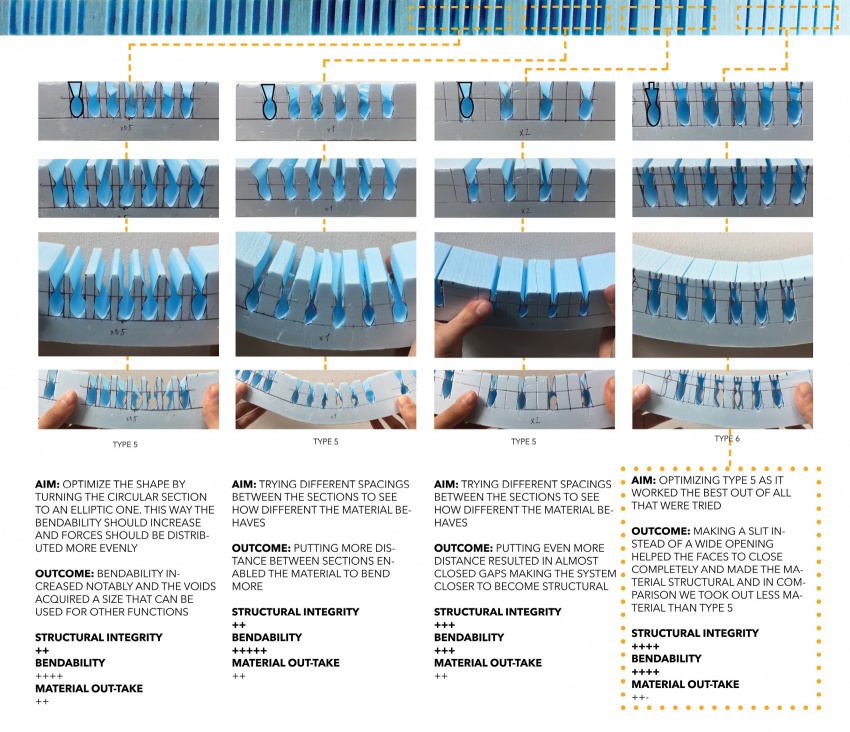

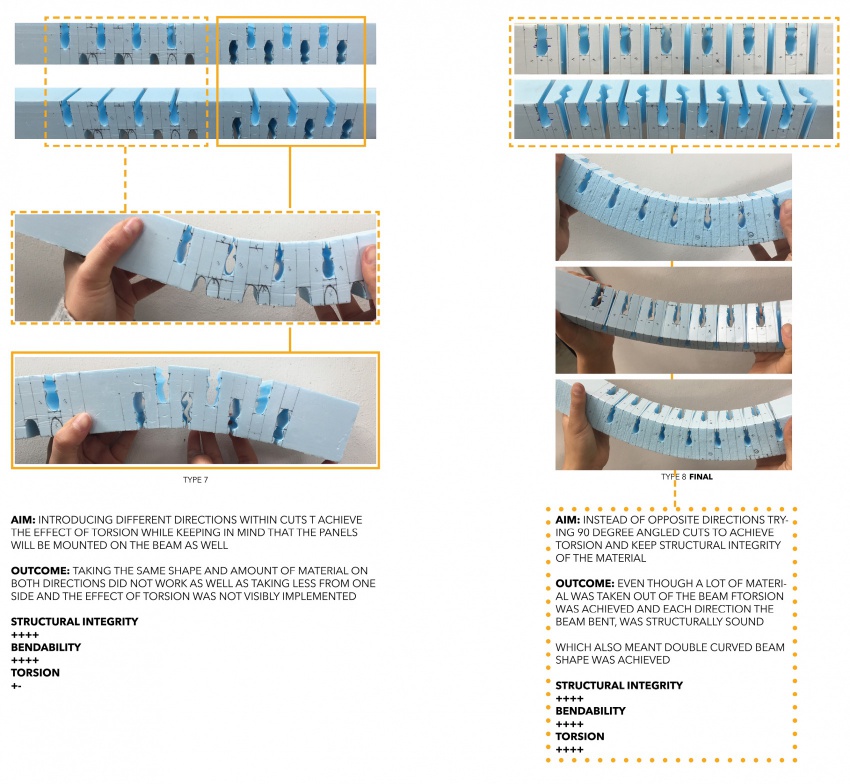

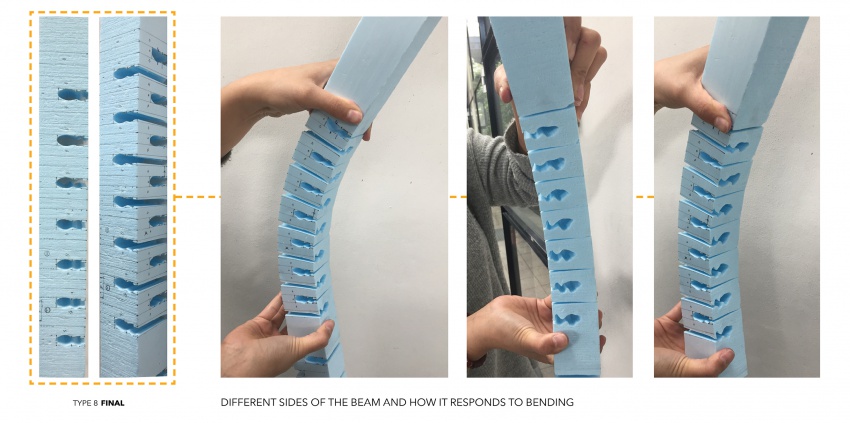

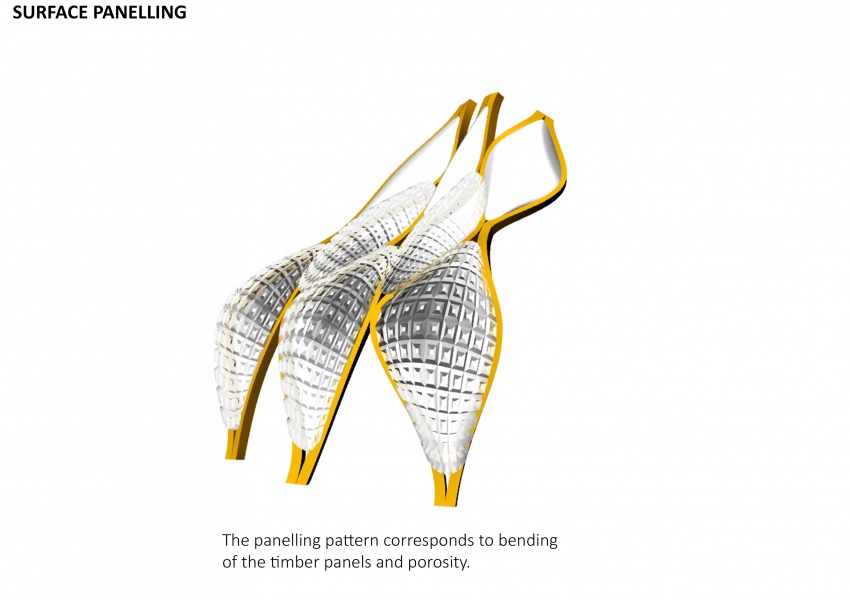

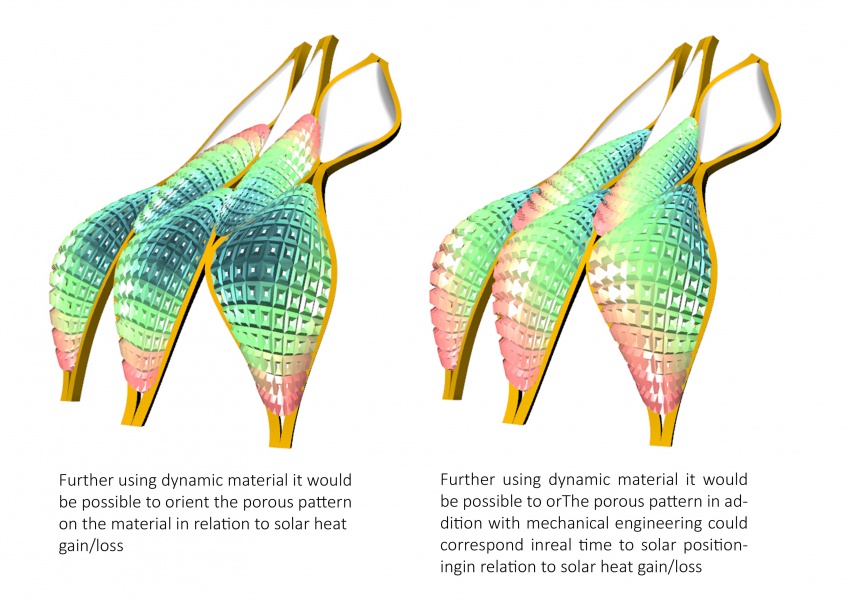

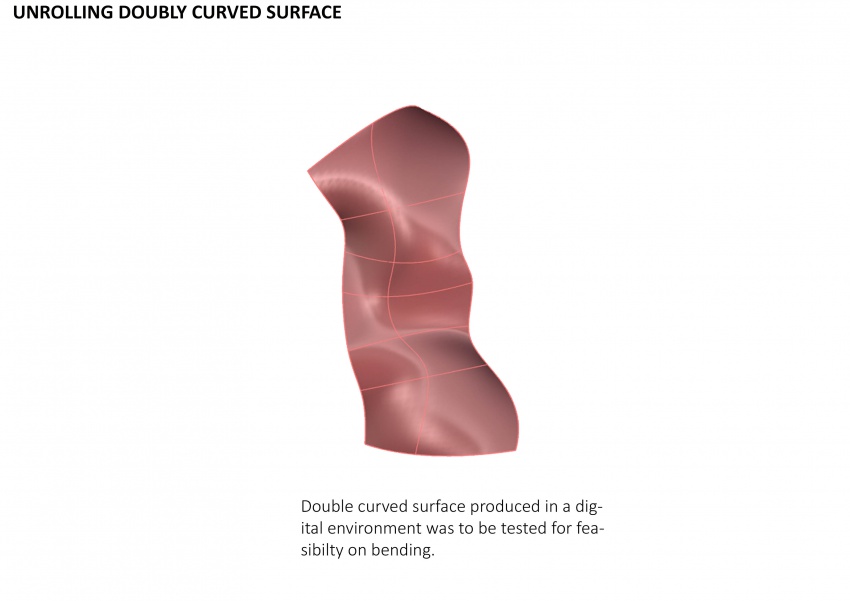

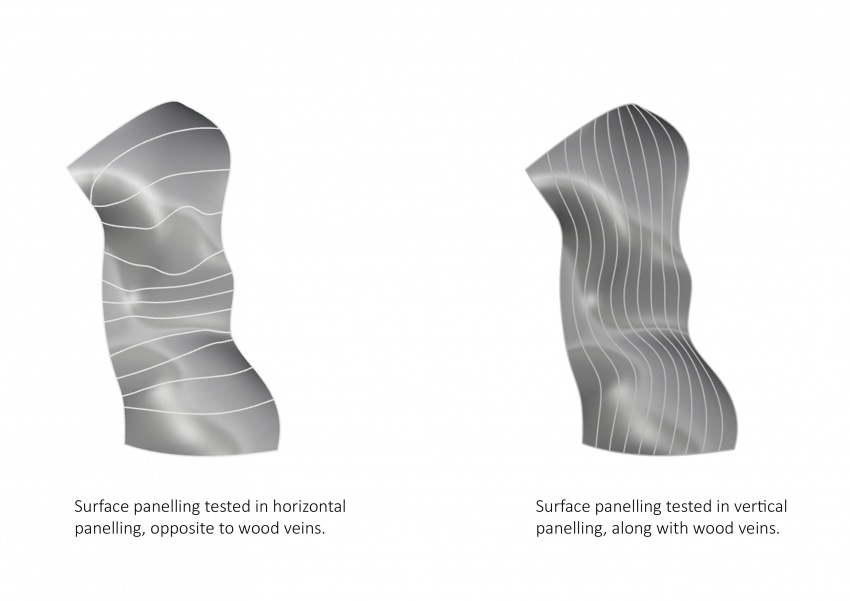

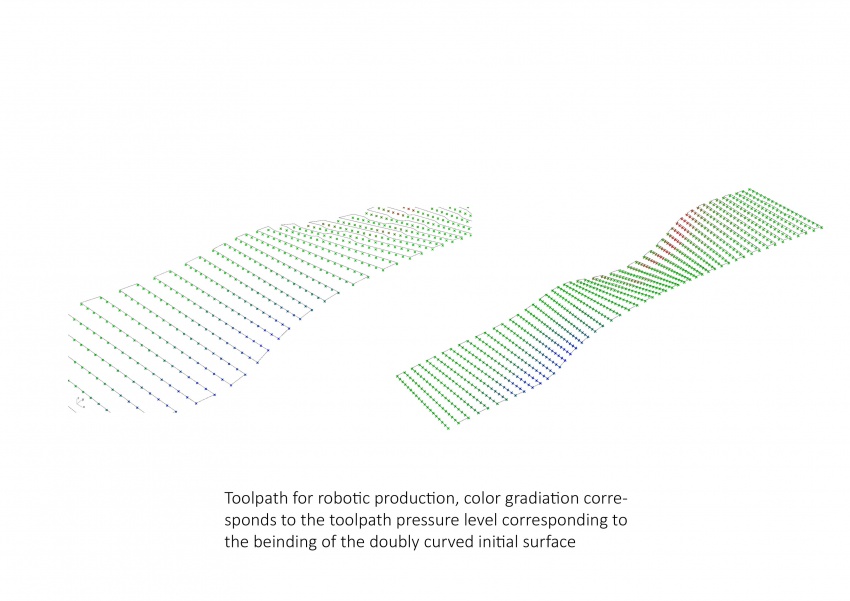

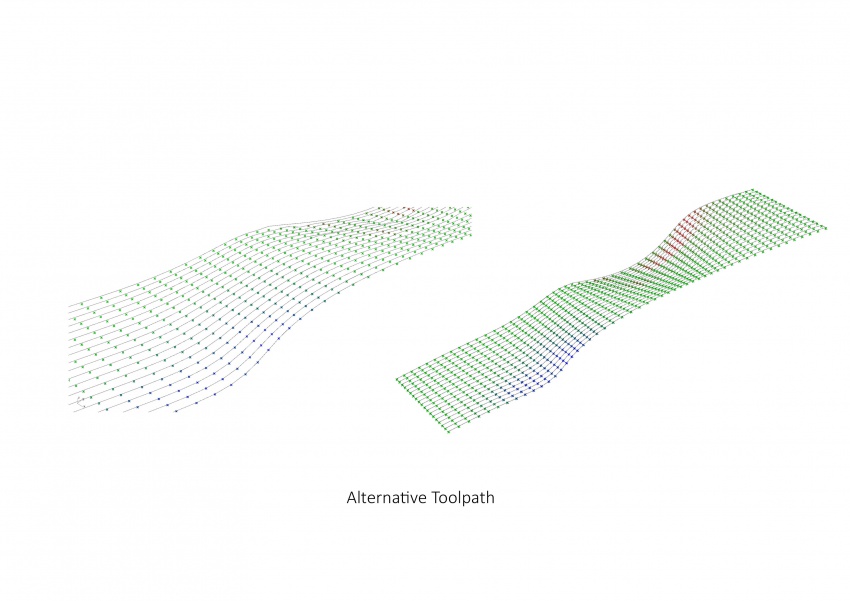

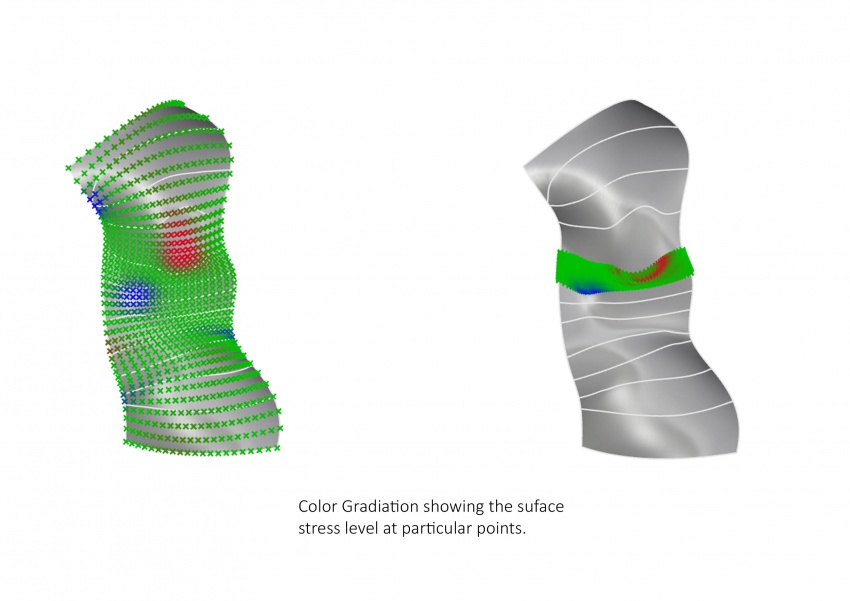

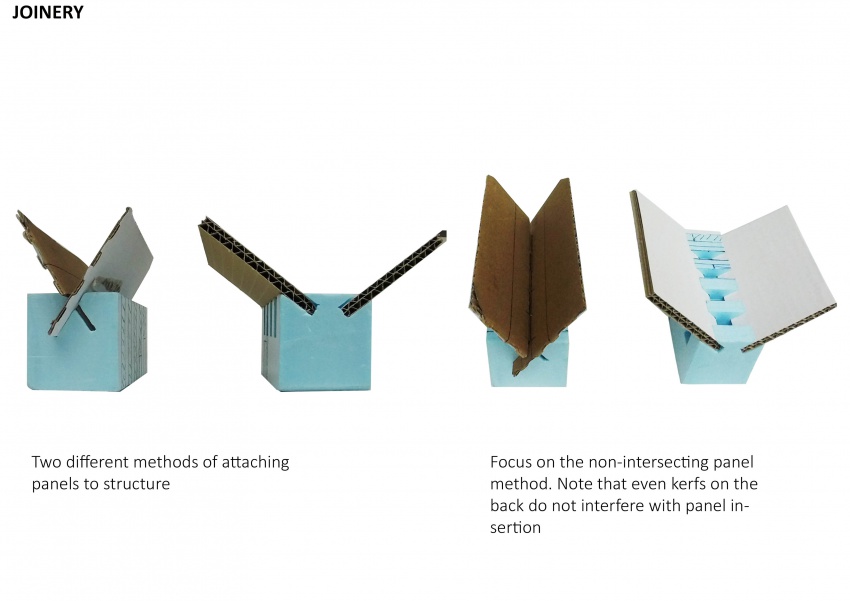

The design of the prototype was constituted by a system of beams and panels. The panels would form the skin of the prototype and were characterised by environmentally and structurally informed porosity. Each was double-curved but would follow either negative or positive Gaussian. The beams constituted the main structural backbone and were characterised by bending and torsion. In order to better understand and integrate these two features, different experiments at the micro-scale were performed. Moreover, a computational strategy for the unrolling and consequent robotic production was developed. In order to simplify the different studies in this first step of the research EPS was used but some preliminary studies on wood bending were carried out. While an integration between panels and structure was considered the scope of this prototype, it was eventually conceived that beams of different thicknesses and sizes could be used to create the desired porosity.

DESIGN CONCEPT

STUDIES

ADD STUDY ON WOOD THICKNESS-CURVATURE

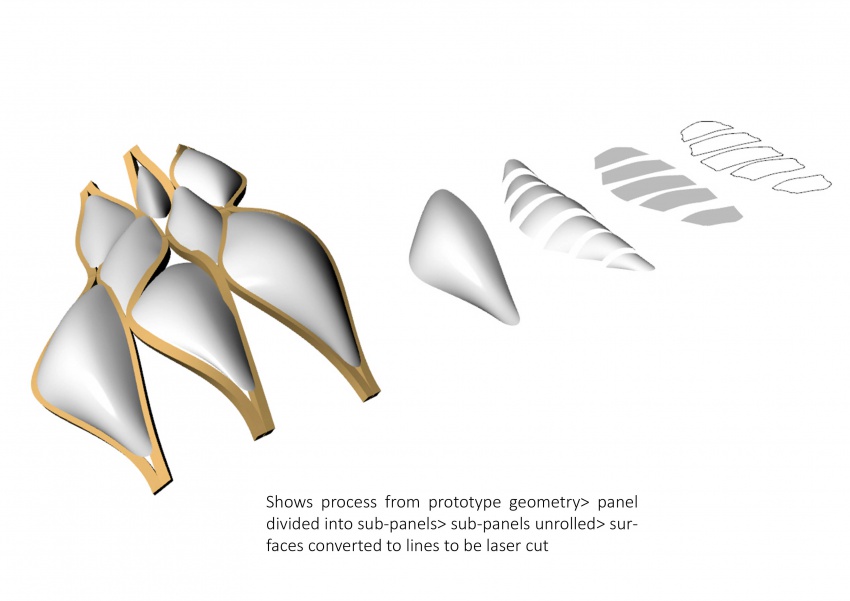

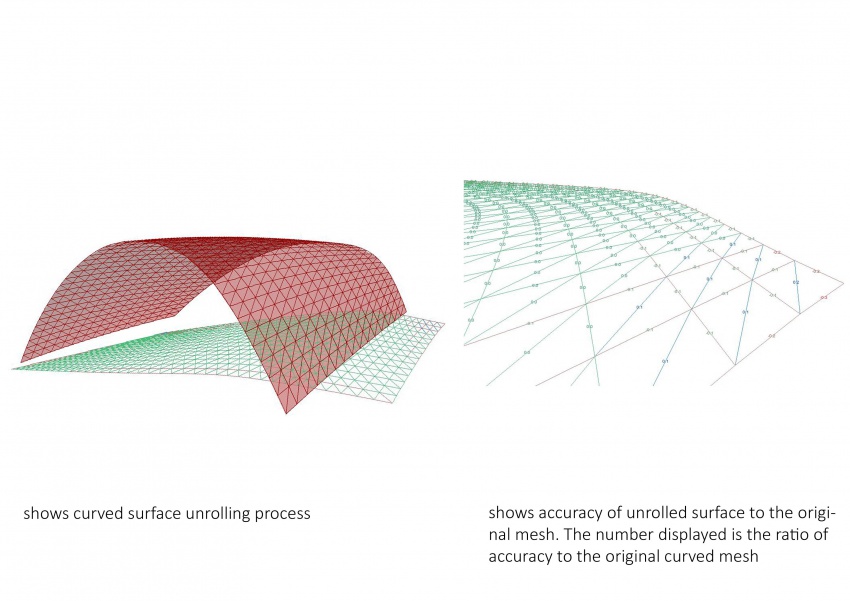

UNROLLING

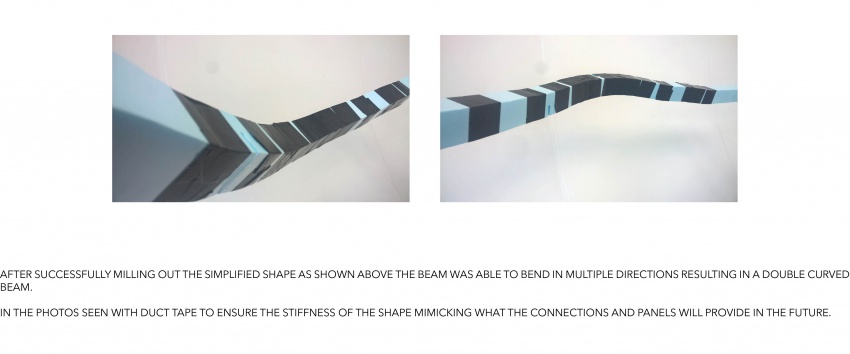

In order to create twisted and curved wooden beams, kerfs of a certain size need to be positioned along the beam. This video shows the positioning that is created by analyzing the curvature.

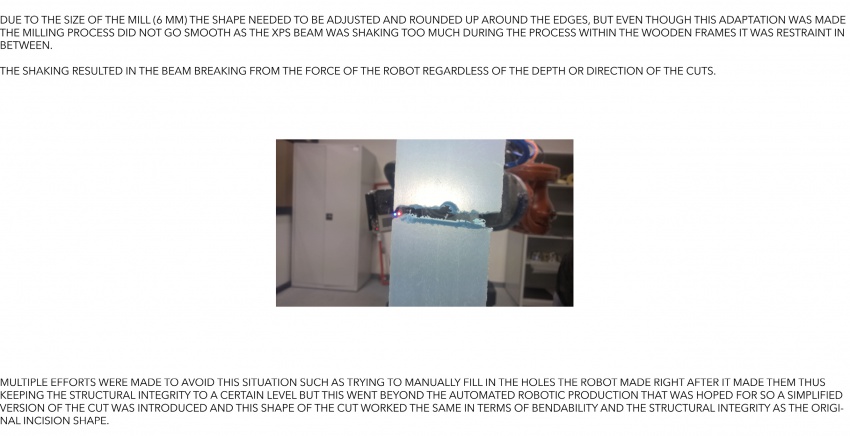

ROBOTIC FABRICATION